Home /

Dyeing Machine Accessories

Dyeing Machine Accessories

Product

Dyeing Machine Accessories

Premium Spare Parts for Efficient and Reliable Dyeing Machine Operations

To ensure the smooth operation and longevity of your dyeing machines, we provide high-quality, precision-engineered spare parts that help maintain efficiency, reduce downtime, and improve overall performance.

Why Choose Our Products?

✔ Industry-Tested for Performance & Reliability ✔ Cost-Effective Solutions

✔ Customizable & Compatible ✔ Warranty & After-Sales Support

1. All-purpose Valves

Available Types:

| 1. | Actuator Ball Valve – Provides precise on/off control for liquids and gases. |

| 2. | Actuator Butterfly Valve – Ideal for quick shut-off and flow regulation. |

| 3. | Actuator Membrane Valve – Ensures accurate dosing and flow control, commonly used in chemical processing. |

| 4. | Cylinder Valve & Piston Valve – Designed for high-pressure applications and precise movement control. |

| 5. | Steam Trap – Removes condensed steam and prevents energy loss in steam systems. |

| 6. | Pressure Reducing Valve (PRV) – Maintains consistent pressure levels to prevent system damage. |

| 7. | Strainer – Filters out debris and impurities to protect machinery and equipment. |

| 8. | Three-Way Valve – Allows multiple flow direction adjustments for more flexible operations. |

2. Sensor & Transmitter

Available Types:

✔ Liquid Level Transmitter (SW1000 & SW3000)

Designed for high-stability level monitoring of dosing tanks. 4-20mA current signal output for precise data transmission. Operates on 24VDC, making it compatible with industrial automation systems.

✔ Analog Float Level Set (For Main Tank Monitoring)

Each set includes:

| 1. | Float Magnet & Float Magnet Tube – Ensures accurate fluid level detection. |

| 2. | Level Indicator – Provides a clear visual display of fluid levels. |

| 3. | Stick Float Level Sensor – High-stability 4-20mA current signal output for real-time monitoring. |

✔ Digital Sensor for Water Level

Our Digital Water Level Sensor is a high-precision, reliable solution for monitoring water levels in dyeing machine tanks. Designed for industrial applications, this sensor provides real-time measurements with digital accuracy, ensuring efficient water management and preventing overflow or dry-run situations.

3. Sensor Cloth/Seam & Detector

Key Features & Benefits:

| 1. | Precise Fabric Cycle Counting – Helps maintain consistency in dyeing operations by accurately detecting fabric movement. |

| 2. | Complete Set for Easy Integration – Comes with a sensor, detector, and cycle magnet, making it easy to install in existing machines. |

| 3. | Enhanced Productivity – Reduces the risk of misalignment and fabric defects, improving overall dyeing quality. |

4. Inverter

Key Features & Benefits:

| 1. | Wide Power Range (0.75 kW - 75 kW) – Suitable for different machine capacities and energy requirements. |

| 2. | Energy-Saving Technology – Optimizes power consumption, reducing operational costs. |

| 3. | Improved Machine Control – Allows precise speed and torque adjustments for better dyeing results. |

| 4. | Built for Industrial Use – Designed to handle continuous, high-load operations without overheating or failure. |

| 5. | Seamless Integration – Compatible with various dyeing machines for effortless upgrades. |

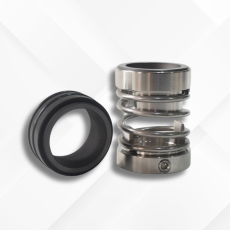

5. Mechanical Seal

Key Features & Benefits:

| 1. | High-Temperature Resistance – Designed to perform in extreme heat and pressure conditions. |

| 2. | Prevents Leakage – Protects machines from fluid loss, reducing waste and improving efficiency. |

| 3. | Durable & Long-Lasting – Made from high-strength materials to withstand continuous industrial use. |

| 4. | Available in Multiple Types & Sizes – Compatible with various dyeing machine models. |

| 5. | Essential for Machine Longevity – Helps maintain optimal machine performance by reducing wear and tear. |

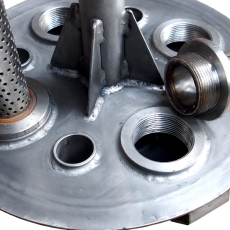

6. Yarn Dyeing Spindle Carrier

Key Features & Benefits:

| 1. | Made from High-Quality Stainless Steel – Resistant to rust, chemicals, and high temperatures. |

| 2. | Customizable Sizes & Specifications – Can be designed to fit specific diameters, spindle heights, and machine requirements. |

| 3. | Optimized for Uniform Dyeing – Ensures proper dye penetration for consistent color quality across all yarn batches. |

| 4. | Durable & Long-Lasting – Built to withstand continuous dyeing cycles without deformation or wear. |

7. Yarn Dyeing Quick Lock and Lock Nut

Key Features & Benefits:

| 1. | Available in Various Sizes & Types – Designed to fit different dyeing machine models. |

| 2. | Fast & Secure Locking Mechanism – Allows quick and easy installation, reducing setup time. |

| 3. | High Durability & Corrosion Resistance – Made from materials that can withstand the harsh dyeing environment. |

| 4. | Enhances Production Efficiency – Minimizes the risk of errors caused by loose or misaligned yarn. |